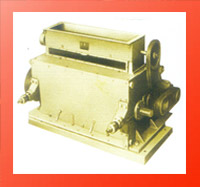

OIL CAKE BREAKERS

The cleaning, dehulling, flaking, and cooking of the oil seeds are the seed preparation stage, where these are readied for oil expelling or extraction. During the seed preparation stage, all the unwanted materials like stones, dust, husks, hulls, metals etc, are separated or removed from the oil seeds. These are further cooked or heated with the use of steam, which conditions the seeds so that the moisture content in them increases. As the moisture increases, it becomes easy to extract oil from the seeds, and it also increases the yield by a large quantity. Apart from using the regular traditional methods of expelling oils from the oil seeds, the use of modern seed processing equipment and oil expellers saves precious time and also increases the output of oil quantity by a large amount.

The cleaning, dehulling, flaking, and cooking of the oil seeds are the seed preparation stage, where these are readied for oil expelling or extraction. During the seed preparation stage, all the unwanted materials like stones, dust, husks, hulls, metals etc, are separated or removed from the oil seeds. These are further cooked or heated with the use of steam, which conditions the seeds so that the moisture content in them increases. As the moisture increases, it becomes easy to extract oil from the seeds, and it also increases the yield by a large quantity. Apart from using the regular traditional methods of expelling oils from the oil seeds, the use of modern seed processing equipment and oil expellers saves precious time and also increases the output of oil quantity by a large amount.The expelling of oil is done with the help of expellers. During the oil expelling process, the seeds are fed through the opening of the machine. The material then passes through the expeller, which crushes the oil seeds. Oil is squeezed through seed crushing then expel through the oil discharging opening and is collected. The solid residue that is left after the squeezing is done exits from the end of the expeller shaft. This solid residue is known as Oil Cakes. These are rich in protein and minerals and are vastly used as animal feed. Some of the oil cakes obtained from seeds such as Castor seeds are known for their toxic and are used as fertilizers and not as animal feed.

These cakes or coarse residue can also be broken up. This breaking up process of the oil cakes is known as cake breaking. Special machines are used for breaking up the oil cakes. Cake Breakers are designed and built with utmost precision so as to give it a strong working construction. They can be either fitted to the press discharging chutes or are mounted directly on the discharge chute of the presses. This equipment consists of beaker blades, which cut the cakes with its scissor cutting action. The expellers / presses produces cakes in the form of large sheets. If these sheets cool down, it becomes difficult to break them. So the main function of cake breakers is to break the cakes before they cool down.

Nowadays, manufacturers are coming up with a wide assortment of cake breaking machines, which are technologically advanced as well as highly user-friendly. The various parts like breaking blades can be easily adjusted as per the requirement of the user. These parts can be easily replaced and the machine needs very low maintenance.