HORIZONTAL PRESSURE LEAF FILTERS

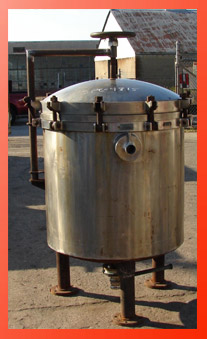

Apart from Vertical Pressure Leaf Filters, another type of filtering machine is known as Horizontal Pressure Leaf Filter. This type of machine is highly standardized and well designed to meet the varied requirements of the oil milling companies to filter vegetable oils. This machine has continuously proved its mettle and renowned as an user-friendly and eco-friendly equipment. Filtering equipments are used to separate or filter all kinds of liquid from impure and unwanted particles that are present in the liquids. Likewise, horizontal pressure leaf filters are used for vegetable oil filtration purpose, and to separate the filtrate and filtered cake, and filtration of slurry from the oils. These are also mainly used in when the filter cakes are sticky and difficult to remove. The cover of this equipment can also be pulled out to enable the easy discharge of the leaves for cleaning.

Apart from Vertical Pressure Leaf Filters, another type of filtering machine is known as Horizontal Pressure Leaf Filter. This type of machine is highly standardized and well designed to meet the varied requirements of the oil milling companies to filter vegetable oils. This machine has continuously proved its mettle and renowned as an user-friendly and eco-friendly equipment. Filtering equipments are used to separate or filter all kinds of liquid from impure and unwanted particles that are present in the liquids. Likewise, horizontal pressure leaf filters are used for vegetable oil filtration purpose, and to separate the filtrate and filtered cake, and filtration of slurry from the oils. These are also mainly used in when the filter cakes are sticky and difficult to remove. The cover of this equipment can also be pulled out to enable the easy discharge of the leaves for cleaning.

Horizontal Pressure Leaf Filter consists of a stack of plates that are attached to a hollow shaft, which further mounted inside a pressure vessel. Each of this plate is covered with a suitable filter medium. Every plate is circular in shape and has radial ribs that are welded to the bottom and also supports a horizontal coarse mesh screen which is covered with a finer woven metal screen or filter cloth which is used to retain the cake. The bottom of the plate slopes towards the hollow central shaft, which lets the filtrate flow freely through circumferential holes and further down the shaft towards the filtrate discharging outlet.

The Horizontal Pressure Leaf Filter also consists of vessels and are constructed vertically to accommodate the plates stack. The bottom design for this type of machines are available in two types namely Conical Bottom and Dished Bottom. The vessels at the bottom have secure cake discharge outlets, which ensures the safe sealing of the tank even under pressure. The tanks which have a conical bottom discharge the cake by gravity, and the tanks with dished bottoms consist of a spade that rakes and transports the cake towards the outlet. Because of this reason, the conical bottoms require more headroom than the dished bottom having the same filtration capacity.

The slurry or mixture is put into the vessel through the opening with the help of pressure. The cake which is retained by the filter medium forms on top of each plate while the filtrate passes through the hollow shaft. The cake is then dried and with the use of pressure, the plate stack are rotated and thus, the cake is released through the cake discharge outlet. The cake outlet interlocks after the discharge with a motor drive as the rotating is continuous.

A wide range of high quality and technologically advanced horizontal pressure leaf filters that are available in the Indian as well as global market today. These are fabricated to give a compact and sturdy construction. Some of the major features of Horizontal Pressure Leaf Filters are as follows:

- High productivity due to the high rate of filtration.

- Highly user-friendly

- Economical operational costs.

- Compact operation and thus no spillage.

- Available in large capacities and various sizes.

- Requires minimum floor spacing.